|

PRODUCT PROPERTY(PPGI AND PPGL) |

SPECIFICATION |

||

|

TESTITEM |

STANDARD |

BASE MATERIAL |

HDGI ALUZINC AL |

|

T BENDING |

0T-3T |

GRADE |

SGCC、DX51/52D、S350GD、ETC OTHER |

|

COMPRESSIVE STRENGTH |

G300 G550 |

THICKNESS |

0.15-1.20MM |

|

IMPACT |

≥9J |

WIDTH |

800-1250MM |

|

MEK(TIME) |

≥100 |

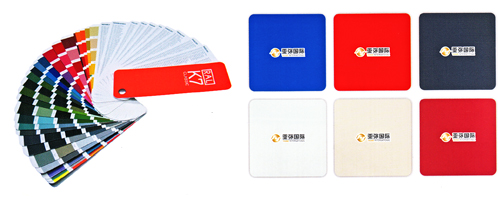

COLOR |

RAL OR ACCORDING TO CUSTOMER'S DEMAND |

|

Bending test |

180 bending degrees |

PAINT |

PE、PVDF SMF、HDP |

|

Salt water spray test |

5% Nacl 35 500hour |

COIL ID |

Φ508mm |

|

Resistance to Chemicals |

5%H2SO4*5Hr 5%NaOH*5Hr |

COAT |

Prime+Top coat 5+15μ Back coat 3+7 μ |

Two coating and two baking method of paint application provides with extra resistance against abrasion,impact,chemical corrosion and weathering.

Way of indirect heat of the curing oven ensure the quality of the surface coating.Plus new cold coating method ensures a firmly adhering zinc layer not peeling during forming.

Durability Character imparts a lasting application life reduces maintenance costs.In the long term produces significant savings for end user.